Tailings facilities, if not managed correctly, could pose significant risks to our employees, host communities and the environment. We manage these facilities as aligned with guidance from locally and globally recognised standards and best practice frameworks that support safe dam design, effective operations and environmental accountability. Our tailings facilities also present a substantial opportunity to advance circular economy outcomes through recovery of valuable materials and reuse of waste streams.

Governance and oversight

Harmony’s operations are required by legislation to hold valid water use licences, environmental permits and authorisations to develop, implement and track compliance with, for example, environmental management programmes that include controls and management measures for TSF management.

Accredited consulting engineers in South Africa and Papua New Guinea compile quarterly reports that provide a detailed independent evaluation of operational performance, safety standards and environmental compliance. These reports are essential tools for monitoring progress, assessing risks and aligning activities with regulatory requirements and industry best practice. Regular updates help stakeholders stay informed, track improvements and identify areas for enhancement, reinforcing a commitment to sustainable operations and continuous improvement across all sites.

We conduct annual audits at our South African TSFs to confirm compliance with local and global applicable safety and environmental standards, and provide an independent evaluation of the facilities, covering structural stability, water management and dust mitigation.

Third-party audits and oversight from our Engineer of Record and the Independent Tailings Review Board (ITRB) are integral components of tailings management processes in Papua New Guinea. This approach aligns to the layered governance aspects of the GISTM. Third-party and independent reviews assess our TSF management practices, including structural integrity, operational efficiency and environmental impacts.

The International Cyanide Management Institute (ICMI) conducts audits across our operations every 18 months to monitor compliance with the Cyanide Code. These independent audits evaluate whether operations meet the rigorous standards set for handling, transporting, storing and disposing of cyanide to minimise the risk to human health and the environment.

Harmony’s TSF management plans and processes are guided by the group mineral waste management standard, the risk management framework and our sustainability framework. Our site construction and operational environmental management plans set out the requirements for effective TSF management. In South Africa, we update our code of practice on mine residue deposits every two years to remain aligned with guidelines from the DMPR, the latest industry standards, environmental regulations and best practices. We submit any updates to the DMPR for review and approval. The board receives regular reporting on facility performance and risk management.

Related policies

Our TSF footprint

South Africa

84 TSFs

(18 operational, 11 under reprocessing, 55 inactive)

Papua New Guinea

2 TSFs

(Hidden Valley TSF 1 is operational; Hidden Valley TSF 2 under construction; Hidden Valley TSF 3 in design/permitting; DSTP approved for Wafi-Golpu (2020))

Australia

0 TSFs

(TSF design completed as part of the updated feasibility study)

Standards and guidance

- South Africa: SANS 10286 (mine residue deposits)

- Australasia: ANCOLD guidelines (risk-based, conservative factors of safety)

- PNG: layered governance elements of the Global Industry Standard on Tailings Management (GISTM)

- International Cyanide Management Code

Our strategy: A proactive and comprehensive approach

Many of our TSFs are legacy facilities older than 40 years. However, all of our TSFs are managed with rigorous operational controls, aligned with best practices. These measures support ongoing stability, address environmental impacts and contribute to the protection of local communities. Our approach integrates water, air quality and biodiversity considerations (keeping final rehabilitation strategies for facilities not earmarked for reclamation in mind).

Implementing robust engineering, dam design and operational management

We manage TSFs following high engineering standard and applying strict water management. Our approach for new and proposed TSFs begins with the comprehensive design phase to deliver safe and stable facilities with structural integrity. We incorporate drainage systems and prevent run-off or seepage into surrounding ecosystems. At Hidden Valley in Papua New Guinea, TSF 1 is designed to seep, with seepage monitored through regular sampling and testing. These measures provide long-term structural and environmental stability and consider factors like rainfall patterns, soil erosion and groundwater interactions. We also implement dust control measures such as dust netting and vegetation planting to reduce airborne particles.

We aim to increase our TSF capacity at Hidden Valley to support the feasibility of extended life-of-mine. The mine’s TSF capacity is constrained, and opportunities to extend the life-of-mine require secure and compliant TSF expansion. We have received regulatory approval for the mining tenement extension and are awaiting a decision on our revised environmental permit. Once necessary approvals are in place, the board will consider the feasibility of extending the life-of-mine.

Active water level management at Hidden Valley

The Hidden Valley mine is located at elevations of 1,700m to 2,800m in steep, forested terrain, which contributes to the high levels of precipitation.

The team is committed to keeping pond levels as low as reasonably practical. This has led to less usage of CAROS, our cyanide destruction circuit, to remove supernatant water from the surface of the dam.

Conducting risk management, layered assurance, oversight and compliance

We embed risk management in the lifecycle of TSFs, from the design and construction of new TSFs, the operating phases and in our final closure designs, including:

- Freeboard legal compliance to maintain safe capacity for excessive rain and operational water levels management with monthly surveys (drone and instrumented)

- Instrumentation, seepage monitoring and erosion control

- Site-level emergency response plans and regular drills; four-siren early-warning system downstream of Hidden Valley

To monitor our performance and compliance with regulations, we conduct independent audits and regular inspections, with management, the deposition contractors and specialist consulting engineers and specialist who assist with the construction of facilities. Additionally, our teams are trained in emergency response.

Our level of alignment with GISTM, or selected elements of the GISTM, is a matter we are continuing to assess noting the practicality and economic feasibility of retrofitting historical TSFs to achieve full alignment with the standard. Read more about the GISTM.

Reducing dust emissions

Harmony Gold implements a variety of measures to control dust from TSFs key measures include:

- Revegetation and phytoremediation involves planting indigenous trees, grass and other vegetation on exposed TSF surfaces to create a sustainable basal cover and prevent wind erosion. Certain plants or trees species can absorb, degrade or immobilise environmental pollutants or contaminants. This approach enhances ecological restoration of affected areas, stabilises soil and reduces erosion while providing long-term solutions to TSF pollution management.

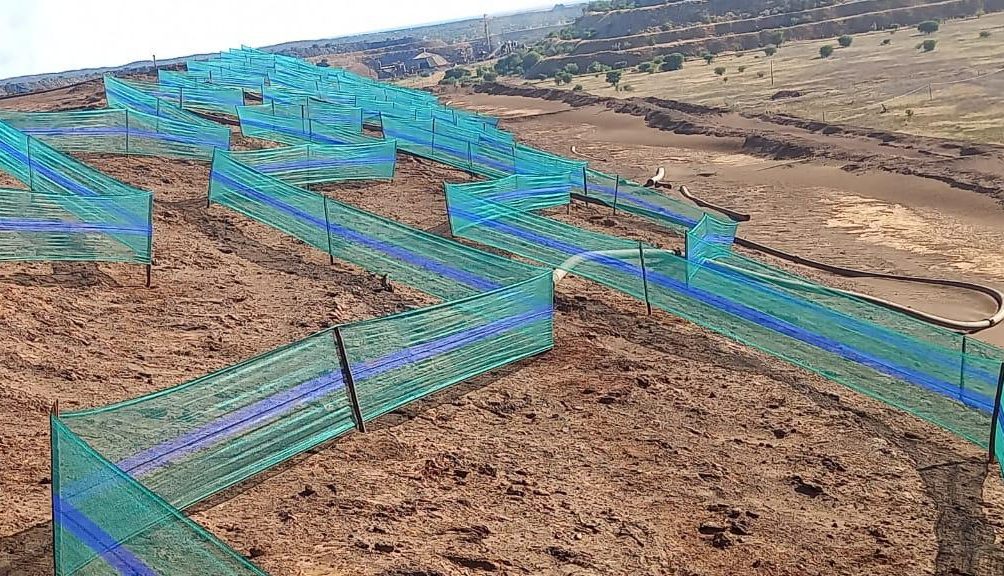

- Dust netting barriers to reduce wind speed and subsequent dust fallout in surrounding areas.

- Water and chemical dust suppressants on TSF surfaces and roads bind fine particles and prevent them from becoming airborne.

Read more about these measures in Air quality

Innovation in tailings reclamation

Construction is underway of the FSS 6 TSF reclamation pump station in the Free State. An innovative feature of the FSS reclamation site is the strategic positioning of its main sump. Unlike other sites, this design enables full dam coverage without requiring the barge to be moved, thereby adding flexibility and operational ease.

Retreating and reclaiming South African TSFs

Tailings retreatment offers substantial competitive advantages and environmental benefits (on completion of reclamation). It tends to be a lower-risk, non-labour intensive, low-energy usage, safer and lower-cost option to conventional mining. Tailings retreatment plays a critical role in supporting a circular economy by recovering valuable minerals from previously discarded waste, reducing the need for new extraction and minimising environmental impacts.

We are exploring the feasibility for reprocessing several inactive TSFs in the Free State, Gauteng and North West. This will also enable the rehabilitation of reclaimed TSF footprints. All reclaimed material will be deposited on existing, recommissioned or where required, new TSFs.

All new and proposed facilities are designed to prevent seepage and reduce the risk of contamination to surrounding land and groundwater. The re-engineered geomembrane liner, as used in the construction of the Kareerand TSF extension for example, is more advanced than the current required class C barrier and offers enhanced performance by significantly reducing groundwater impact risks. The innovative design maximises water recovery, supporting a higher return of water for reuse.

Collaboration and partnerships

In South Africa, we are collaborating with a local supplier to transfer mine rehabilitation skills to local communities while completing the Doornkop TSF dust mitigation project. At Hidden Valley, we collaborate with the MRA regularly to provide dam performance and address any safety risks and operational issues. We also engage with third-party auditors and the ITRB.

Explore related Case studies

Further information

Additional performance-related discussions and data may be found in these publications.